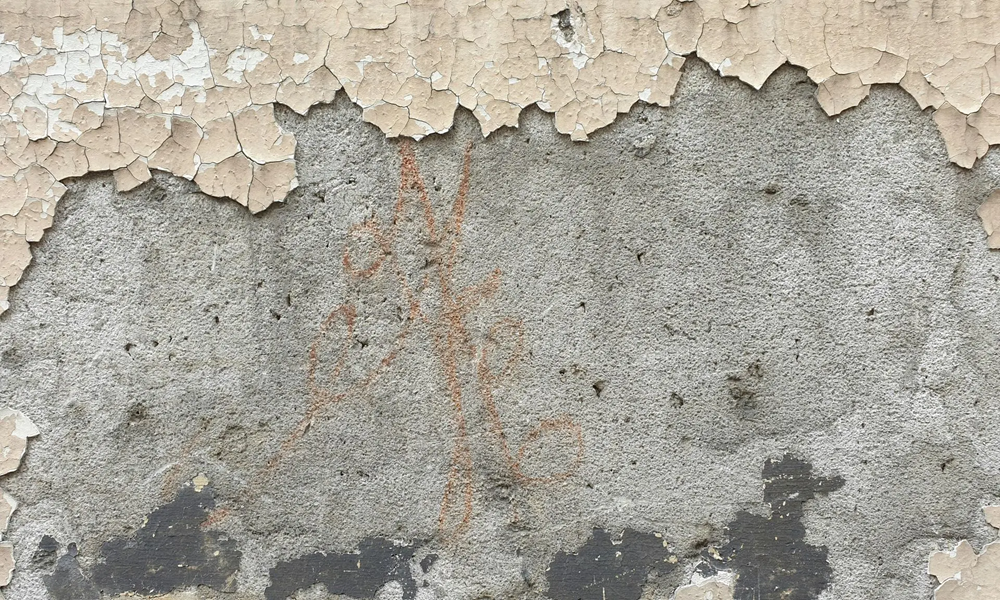

Hairline cracks in buildings are a common issue that can cause concern for property owners. These small, fine cracks can appear in walls, ceilings, floors, and other structural elements. While often seen as a minor problem, hairline cracks can be indicative of underlying issues that, if left unaddressed, may lead to more significant damage. This article will explore the causes of hairline cracks, their implications, and how to address them effectively.

What Are Hairline Cracks?

Hairline cracks are very thin cracks, usually less than 1mm wide, that appear on the surface of building materials like plaster, concrete, or brick. They are often superficial but can sometimes indicate deeper structural problems.

Common Causes of Hairline Cracks

1. Thermal Expansion and Contraction

Building materials expand and contract with temperature changes. This natural movement can cause hairline cracks to form, especially in areas exposed to significant temperature variations.

2. Drying Shrinkage

As concrete, plaster, or mortar cures and dries, it can shrink slightly. This shrinkage can lead to the formation of hairline cracks, particularly in new constructions or recently renovated areas.

3. Structural Movement

Buildings settle over time due to changes in the soil, foundation settling, or structural adjustments. This movement can cause hairline cracks to appear in walls and ceilings.

4. Poor Construction Practices

Improper mixing of materials, inadequate curing times, or poor workmanship can contribute to the development of hairline cracks. Ensuring high construction standards is crucial to minimize such issues.

5. Moisture Infiltration

Moisture penetration can weaken building materials and cause hairline cracks. This is especially common in areas with inadequate waterproofing or drainage systems.

Implications of Hairline Cracks

While hairline cracks are often superficial, they should not be ignored. If left unaddressed, they can:

- Worsen Over Time: Small cracks can expand and deepen, leading to more significant structural issues.

- Allow Water Ingress: Cracks can provide pathways for water to enter the building, causing moisture damage, mold growth, and further weakening of the structure.

- Reduce Aesthetic Appeal: Visible cracks can detract from the appearance of a property, affecting its value and desirability.

- Indicate Underlying Problems: In some cases, hairline cracks may signal more serious underlying issues, such as foundation problems or structural instability.

Addressing Hairline Cracks

1. Inspection and Assessment

Conduct a thorough inspection to determine the extent and cause of the cracks. This may involve examining the building’s foundation, structural elements, and environmental conditions. Consulting a structural engineer or building professional can provide valuable insights and recommendations.

2. Cleaning and Preparation

Clean the cracked area to remove any loose debris, dirt, or dust. This ensures better adhesion of repair materials and allows for a more effective repair.

3. Filling the Cracks

For minor, superficial cracks, use a suitable crack filler or sealant. Products like acrylic fillers, polyurethane sealants, or epoxy resins are effective for filling hairline cracks. Follow the manufacturer’s instructions for application and curing times.

4. Monitoring and Maintenance

Regularly monitor the repaired areas for any signs of new cracks or changes in existing ones. Implement a maintenance routine to address any issues promptly, ensuring the longevity and integrity of the building.

5. Addressing Underlying Causes

If the cracks are due to underlying issues like structural movement or moisture infiltration, take corrective measures to address these problems. This may involve improving drainage systems, reinforcing structural elements, or implementing better waterproofing solutions.

6. Professional Assistance

For significant or persistent cracks, seek professional assistance. Structural engineers and building experts can provide comprehensive assessments and recommend appropriate solutions to ensure the stability and safety of the building.

Conclusion

Hairline cracks in buildings are a common but manageable issue. Understanding their causes and implications is essential for addressing them effectively. By conducting regular inspections, using suitable repair materials, and addressing underlying problems, property owners can maintain the structural integrity and aesthetic appeal of their buildings. Taking proactive steps to manage hairline cracks ensures a safe and durable living or working environment.