Waterproofing is a crucial aspect of construction that ensures the longevity and durability of buildings. Among the various waterproofing methods available, polyurethane injection has emerged as a versatile and highly effective solution.

What is Polyurethane Injection?

Polyurethane injection is a waterproofing technique that involves injecting a polyurethane resin into cracks, joints, and voids within concrete or masonry structures. The resin reacts with water, expanding and forming a watertight seal. This method is widely used for both negative and positive waterproofing applications, providing a robust solution to prevent water ingress and protect structural integrity.

How Polyurethane Injection Works

Polyurethane injection involves a series of steps to ensure effective waterproofing:

- Assessment and Preparation:

- Inspection: Identify all cracks, joints, and voids where water ingress is occurring.

- Drilling: Drill holes at strategic points along the affected areas to insert injection ports (packers).

- Injection Process:

- Mixing: Prepare the polyurethane resin, ensuring it is mixed to the correct consistency.

- Injection: Use high-pressure pumps to inject the resin through the packers into the cracks and voids. The resin reacts with any present moisture, expanding and filling the spaces.

- Curing and Sealing:

- Curing: Allow the injected resin to cure, forming a flexible, watertight seal.

- Final Inspection: Conduct a thorough inspection to ensure all cracks and voids are adequately sealed.

Benefits of Polyurethane Injection

Polyurethane injection offers several advantages that make it a preferred choice for waterproofing:

- Effective Waterproofing:

- The expanding nature of polyurethane allows it to fill even the smallest cracks and voids, providing a comprehensive waterproof barrier.

- Durability:

- Once cured, polyurethane forms a durable, flexible seal that can withstand structural movements and environmental conditions.

- Versatility:

- Suitable for a wide range of applications, including basements, tunnels, retaining walls, foundations, and more.

- Minimal Disruption:

- The injection process is carried out internally, causing minimal disruption to building occupants and operations.

- Cost-Effective:

- Compared to extensive excavation and external waterproofing methods, polyurethane injection is often more affordable and quicker to apply.

Applications of Polyurethane Injection

Polyurethane injection is used in various construction scenarios to address water ingress and structural issues:

- Basement Waterproofing: Sealing cracks and joints in basement walls and floors to prevent water seepage.

- Tunnel Waterproofing: Addressing leaks and water ingress in tunnels and underground structures.

- Foundation Repair: Strengthening and waterproofing foundations by sealing cracks and voids.

- Concrete Structures: Repairing and waterproofing concrete structures, including bridges, dams, and parking garages.

Basement Waterproofing in Nairobi, Kenya

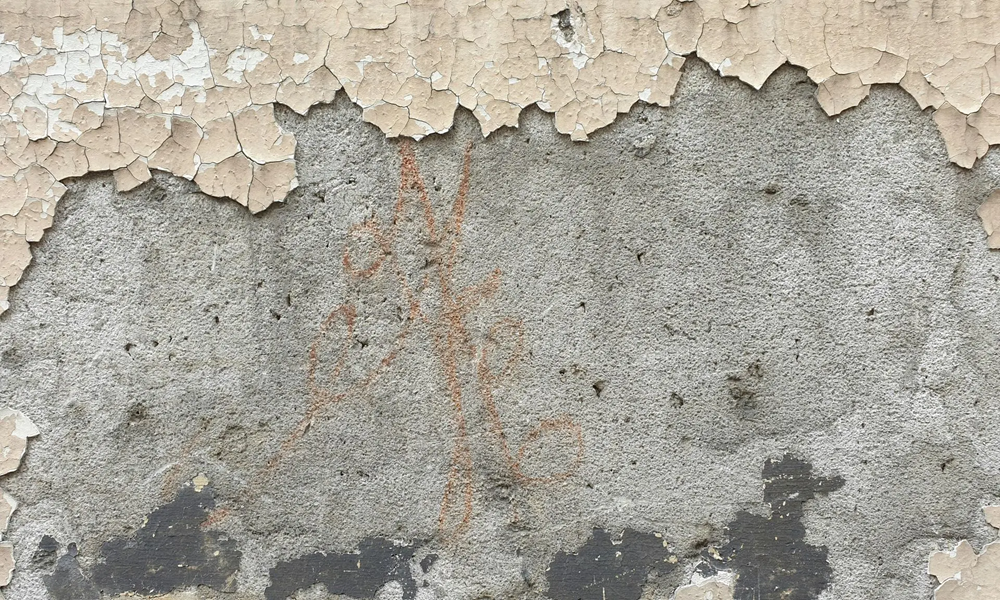

The Challenge

In Nairobi, a commercial building experienced severe water ingress in its basement. The water infiltration was causing significant damage to the structure and creating an unhealthy environment for occupants. Traditional positive waterproofing methods were not feasible due to access issues and the high cost of exterior excavation.

The Solution

A negative waterproofing solution was implemented using polyurethane injection. The process involved the following steps:

- Assessment: A thorough inspection was conducted to identify all points of water ingress and determine the extent of the damage.

- Preparation: Injection ports (packers) were strategically placed into drilled holes along the affected areas.

- Injection: High-pressure pumps were used to inject polyurethane foam into the packers. The polyurethane expanded to fill cracks and voids, creating a watertight seal.

- Curing: The polyurethane was allowed to cure, forming a flexible yet durable barrier against water ingress.

Results

The negative waterproofing intervention successfully sealed all points of water ingress, preventing further water penetration into the basement. The interior spaces were protected from water damage, mold growth was halted, and the structural integrity of the building was preserved.

Benefits Realized

- Cost Savings: The negative waterproofing method was more affordable than extensive exterior excavation.

- Minimal Disruption: The work was completed from the inside, causing minimal disruption to building occupants.

- Long-Term Protection: The polyurethane provided a durable and flexible barrier, ensuring long-term protection against water ingress.

Polyurethane injection is a powerful tool in the arsenal of waterproofing techniques. Its ability to effectively seal cracks and voids, coupled with its durability and versatility, makes it an ideal solution for a wide range of applications. Whether you are dealing with a leaky basement in Nairobi or a complex infrastructure project elsewhere, polyurethane injection can provide the robust waterproofing needed to protect and preserve your structures.

Reach out to GreenBuild Waterproofing Solutions on 0700288388